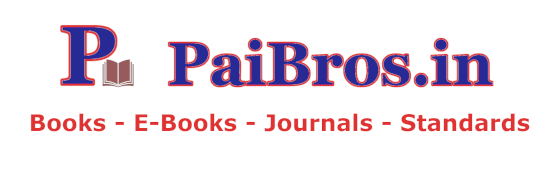

Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical Industries

Original price was: ₹10,422.00.₹8,337.60Current price is: ₹8,337.60.

ISBN: 9780128014073

Author/Editor: Alireza Bahadori

Publisher: Elsevier

Year: 2015

1 in stock (can be backordered)

Description

With the oil and gas industry facing new challenges?deeper offshore installations, more unconventional oil and gas transporting through pipelines, and refinery equipment processing these opportunity feedstocks–new corrosion challenges are appearing, and the oil and gas industry? infrastructure is only as good as the quality of protection provided and maintained. Essentials of Coating, Painting, and Linings for the Oil, Gas, and Petrochemical Industries is the first guide of its kind to directly deliver the necessary information to prevent and control corrosion for the components on the offshore rig, pipelines underground and petrochemical equipment. Written as a companion to Cathodic Corrosion Protection Systems, this must-have training tool supplies the oil and gas engineer, inspector and manager with the full picture of corrosion prevention methods specifically catered for oil and gas services. Packed with real world case studies, critical qualifications, inspection criteria, suggested procedure tests, and application methods, Essentials of Coating, Painting, and Linings for the Oil, Gas and Petrochemical Industries is a required straightforward reference for any oil and gas engineer and manager

Product Properties

| Year of Publication | 2015 |

|---|---|

| Table of Contents | Dedication About the Author Preface Acknowledgments Chapter 1: Surface Preparation for Coating, Painting, and Lining Abstract 1.1. Introduction 1.2. Selection of Cleaning Method 1.3. Cleanliness of the Surfaces 1.4. Temporary Protection of Prepared Surfaces Against Corrosion and Contamination 1.5. Preparation of Surfaces Protected by Temporary Coatings 1.6. Inspection and Testing 1.7. Quality Systems 1.8. Procedure Qualification 1.9. Degreasing 1.10. Hot Solvent Cleaning Method 1.11. Aqueous Alkaline and Detergent Cleaning 1.12. Steam Cleaning 1.13. Testing for Lack of Grease 1.14. Notes on Degreasing 1.15. Pickling 1.16. Cleaning and Preparation of Metal Prior to Pickling 1.17. The Pickling Process 1.18. Electrochemical Pickling 1.19. Treatment of Metal After Pickling 1.20. Appearance of Pickled Surfaces 1.21. Test Methods?etermining the Acid and Iron Content of Pickle Baths 1.22. Precautions 1.23. Manual Cleaning (Hand and Power Tool Cleaning) 1.24. Power Tool Cleaning 1.25. Manual Cleaning of Nonferrous Metals 1.26. Precautions 1.27. Blast cleaning 1.28. Choice of Method of Blast Cleaning 1.29. Abrasives 1.30. Before and After Blast Cleaning 1.31. Testing the Cleanliness of the Blasted Surface 1.32. Precautions 1.33. Flame Cleaning 1.34. Surface Preparation of Iron and Steel 1.35. Chemical Smoothing Process for Steel 1.36. Anodic Etching for Ferrous Metals 1.37. Cleaning of Shop-Primed Steel Surfaces Prior to Overcoating 1.38. Surface Preparation of Stainless Steel 1.39. Preparation of Stainless Steel for Electroplating 1.40. Surface Preparation of Nonferrous Metals 1.41. Surface Preparation of Metallic Surfaces for Maintenance 1.42. Surface Preparation of Imperfect Metallic Surfaces 1.43. Surface Preparation of Concrete 1.44. Types of Preparation 1.45. Test Methods 1.46. Surface Preparation of Precast Concrete Blocks 1.47. Inspection and Rejection 1.48. Application of Degreasing Methods 1.49. Spray or Jet Cleaning Process 1.50. Brushing or Wiping Process 1.51. Electrolytic Cleaning Process 1.52. Ultrasonic Cleaning Process 1.53. Application Process of Blasting 1.54. Abrasive Breakdown 1.55. General Notes on Use of Abrasives 1.56. Blasting Process and Equipment 1.57. Centrifugal Blasting 1.58. Water Blasting (Hydroblasting) 1.59. Drying Parts After Aqueous Cleaning and Before Coating 1.60. Surface Preparation of Plaster, Brick, Stone, and Wood 1.61. Preparation of Brick and Stone 1.62. Preparation of External Rendering 1.63. Preparation of Wood 1.64. Types and Application of Fillers and Stoppers for Nonmetallic Surfaces 1.65. Treatment of Organic Growths Chapter 2: Engineering and Technical Guidelines for Painting Abstract 2.1. Corrosive Environments 2.2. Water Immersion Environments 2.3. Chemical Environments 2.4. Marine Environments 2.5. Underground Environments 2.6. Adhesion of Paint to the Substrate 2.7. Facilities for the Application of Coatings 2.8. Requirements 2.9. Surface Preparation 2.10. Paint Application 2.11. Priming and Painting 2.12. Treatment of Specific Surfaces 2.13. High-Temperature Surfaces 2.14. Refrigerated Surfaces 2.15. Paint Schedule 2.16. Paint Color Schedule 2.17. Corrosion prevention by paint coatings 2.18. Barriers 2.19. Electrical Methods 2.20. Chemical Inhibition 2.21. Characteristics of Protective Systems 2.22. Two-Pack, Chemical-Resistant Paints 2.23. Bituminous Coatings 2.24. Characteristics of Metallic Coatings 2.25. Characteristics of Some Other Protective Systems 2.26. Internal Painting of Aboveground Steel Tanks, LPG Spheres, and Vessels 2.27. Typical Refinery Painting Systems Schedule for Steel Surfaces Recommended Scheme Chapter 3: Application Methods of Paint and Preparation for Use Abstract 3.1. Introduction 3.2. Paint Materials 3.3. Paint Application Color Coding 3.4. Components or Work Pieces 3.5. Inspection and Testing 3.6. Quality Systems 3.7. Procedure Qualifications 3.8. Metal Surface Treatment (Conversion Coatings) 3.9. Preparation of Paint Before Use 3.10. Application Methods of Paint 3.11. Application Procedures for Generic Groups of Paint 3.12. Vinyl and Chlorinated Rubber Paint 3.13. Zinc-Rich Paint 3.14. Urethane Coatings 3.15. Latex Paints for Steel 3.16. Painting of Ferrous Metals 3.17. Field and Touch-up Painting of Steel 3.18. Maintenance Painting of Steel 3.19. Painting of Stainless Steel 3.20. Painting of Nonferrous Metals, Including Metal-Coated Surfaces 3.21. Painting of Plaster, Concrete, Brick, Block and Stone 3.22. Treatment of Stains 3.23. Plaster 3.24. Concrete 3.25. Brick and Stone 3.26. Precast Concrete Blocks and External Rendering 3.27. Method of Measuring Moisture Content 3.28. Painting of Wood 3.29. Paint Systems (Opaque Coating) for Wood 3.30. Natural Finish System (Transparent Coating) for Wood 3.31. Drying and Handling 3.32. Inspection Procedure 3.33. Safety 3.34. Prevention of Fire and Explosion 3.35. Prevention of Toxic Hazards 3.36. Prevention of Health Hazards 3.37. Paint Schedules for Non-metallic Surfaces 3.38. Conversion coating (metal surface treatments) 3.39. Phosphate Coating 3.40. Other Types of Phosphate Coating 3.41. Chemical Control of Phosphating Processes 3.42. Repair of Phosphate Coatings 3.43. Inspection Methods 3.44. Chromate Treatment 3.45. Surface Treatment of Ferrous Metals 3.46. Treatment of Nonferrous Surfaces Chapter 4: Engineering and Technical Fundamentals of Lining Abstract 4.1. Purpose of Lining 4.2. Lining Design 4.3. Compliance 4.4. Design, Fabrication, and Surface Finishing of Equipment to be Lined 4.5. Design of Metal Equipment to be Lined with Inorganic Material 4.6. Selection of Lining Material 4.7. Process Information to be Established 4.8. Material Characteristics to be Considered 4.9. Thermoplastic Resin Lining 4.10. Thermosetting Resin Linings 4.11. Rubber Lining 4.12. Glass and Porcelain Lining 4.13. Ceramic Lining 4.14. Chemical-Resistant Brick and Tile Lining 4.15. Thickness of the Brick Lining 4.16. Refractory Lining 4.17. Cement-Mortar Lining 4.18. Shop-applied Cement-Mortar Lining 4.19. Field-Applied Cement-Mortar Lining 4.20. Bitumen (Asphalt) and Coal-Tar Lining 4.21. Cladding of Pressure Vessels 4.22. Selection of Cladding Materials 4.23. Design 4.24. Cladding of Pipeline with CRA (Nickel-based) 4.25. Effect of Lining Materials on Water Quality Chapter 5: Construction Guidelines for Lining Abstract 5.1. Selection of Process and Material 5.2. Applicator Qualifications 5.3. Inspector Qualifications 5.4. Qualification Testing 5.5. Responsibility for Inspection and Testing 5.6. Sheet-Applied Thermoplastic Resin Lining 5.7. Preparation 5.8. Application of Lining 5.9. Transportation and Storage 5.10. Repair of Lining 5.11. Inspection and Test Methods 5.12. Installation 5.13. Nonsheet-Applied Thermoplastic Resin Lining 5.14. Curing 5.15. Repair of Lining 5.16. Inspection and Test Methods 5.17. Stoved Thermosetting Resin Lining 5.18. Application Methods 5.19. Curing 5.20. Transportation and Storage 5.21. Repair of Lining 5.22. Cold-Curing Thermosetting Resin Lining 5.23. Application Methods 5.24. Rubber Linings 5.25. Installation of Rubber-Lined Parts 5.26. Repair of Lining 5.27. Bitumen, Asphalt, and coal-tar lining 5.28. Preparation 5.29. Drying 5.30. Inspection and Test Methods 5.31. Glass and Porcelain Linings 5.32. Curing 5.33. Transportation 5.34. Installation 5.35. Repair of Lining 5.36. Ceramic Lining 5.37. Curing 5.38. Transportation 5.39. Repair of Lining 5.40. Inspection and Tests 5.41. Brick and Tile Lining 5.42. Preparation 5.43. Method of Lining 5.44. Application of Lining for Metallic Equipment 5.45. Application of Lining for Concrete Construction 5.46. Curing and Prestressing 5.47. Repair of Lining 5.48. Cement-Mortar Lining 5.49. Transportation 5.50. Installation and Joining 5.51. Seal Materials 5.52. Repair of Lining 5.53. Inspection and Rejection (for Lined Pipe) 5.54. Inspection During Application 5.55. Refractory Lining 5.56. Application Methods 5.57. Refractory Cement Lining 5.58. Curing and Drying 5.59. Transportation 5.60. Safety 5.61. Toxicity of Materials 5.62. Lining Continuity and Tests 5.63. Application of Rubber Sheet Lining in Pipe 5.64. Tube Inflation 5.65. Curing of Brick Lining with Acidic Liquid 5.66. Curing of Tank Lining 5.67. Reasons for Heating Lining Materials 5.68. Temperature Controls 5.69. Testing and Inspection 5.70. Air-Dried Lining Materials 5.71. Chemically Converted Materials 5.72. Baking-Type Materials Chapter 6: Engineering Guidelines for Protective Coatings in Buried and Submerged Steel Structures Abstract 6.1. Field of Application 6.2. Purpose of Coating 6.3. Coatings and Cathodic Protection 6.4. Coating Design and Desirable Characteristics of Coatings 6.5. General Requirements 6.6. Coating Schedule 6.7. Characteristics of Specified Coatings 6.8. Selection of Coating to be Used 6.9. Coating Application 6.10. Description of Coating Systems 6.11. Temperature Limitations (The Application and Service Temperatures) 6.12. Extruded Polyethylene Coating 6.13. Concrete 6.14. Coating of Subsea Pipelines Chapter 7: Fundamentals of Protective Coating Construction Abstract 7.1. General Conditions for Application 7.2. Coating Materials 7.3. Material Handling and Storage 7.4. Identification of Coating Materials 7.5. Pipe Identification 7.6. Protection of Weld End Preparation 7.7. Surface Preparation 7.8. Coating Procedure Tests 7.9. Inspection and Testing (Quality Control) 7.10. Quality System 7.11. Test Certificates 7.12. Procedure Qualification 7.13. Production Coating Requirements 7.14. Inspection and Rejection of Finished Coating 7.15. Coating Requirements and Test Methods 7.16. Defect Rate 7.17. Repairs 7.18. Stripping of Coating 7.19. Transportation, Handling, and Storage 7.20. Cold-Applied Tape Coatings 7.21. Surface Preparation Prior to Coating 7.22. Coating Application 7.23. Coating of Welded Field Joints 7.24. Mechanical Coupling and Pipe Ends 7.25. Coating Repair 7.26. Fusion-Bonded Epoxy Coating 7.27. Field Coating of Welded Joints 7.28. Coating Repair 7.29. Hot-Applied Enamel Coating 7.30. Preparation of Enamel for Use 7.31. Coating of Joint, Fitting, and Connections 7.32. Coating Repair 7.33. Concrete Coating of Line Pipe 7.34. Coating Process 7.35. Inspection and Testing 7.36. Repairs and Rejection 7.37. Polyethylene Coating Application 7.38. Coating Application of Fittings and Connections 7.39. Cold-Applied Primer and Prefabricated Tape 7.40. Polyethylene Heat-Shrinkable Coatings 7.41. Asphalt Mastic Coating 7.42. Installation of Coated Pipe and Backfilling 7.43. Hoisting 7.44. Pipe Bedding and Trench Backfill 7.45. Backfilling Chapter 8: Materials and Construction for Three-Layer Polyethylene Coating Systems Abstract 8.1. Requirements for Factory-Applied Coating Materials and Testing Methods 8.2. Coating Materials 8.3. Epoxy Powder 8.4. Basic Properties and Tests for Cured Coatings 8.5. Basic Properties and Tests for Bonding Agents (Adhesives) 8.6. Basic Properties and Tests for Polyethylene 8.7. Color 8.8. Quality Systems 8.9. Materials 8.10. Protection of Pipe End Preparation 8.11. Surface Preparation 8.12. Coating Procedure Tests 8.13. Inspection and Testing (Quality Control) 8.14. Quality Systems 8.15. Coating Procedure Qualifications 8.16. Coating Procedure Approval Tests 8.17. Short-Term Approval Tests 8.18. Production Coating Requirements 8.19. Inspection of Finished Coating 8.20. Coating Requirements and Test Methods 8.21. Handling and Storage Requirements 8.22. Transportation Loading 8.23. Stripping of Coating 8.24. Holiday Detection of Coatings 8.25. Coating of Butt Joints?aterial Application Charts 8.26. Approval of Field Joint and Fitting Coating Equipment and Applicators 8.27. Coating Material 8.28. Requirements for Factory-Applied Coating 8.29. Coating System Application 8.30. Quality Control Requirements 8.31. Some Test Procedures 8.32. Repair of Coating Damage Chapter 9: Technical Guidelines for Material Selection?art 1 Abstract 9.1. Asphalt Mastic (Cold-Applied) 9.2. Material and Equipment Standards for Vinyl Paint (Aluminum) as Intermediate and Topcoat (Finish) 9.3. Red Lead, Iron Oxide, Raw Linseed Oil, and Alkyd Primer 9.4. Red Lead, Iron Oxide, and Alkyd Intermediate Paint 9.5. White Alkyd Paint for Topcoat (Finish) 9.6. Colored Alkyd Paint for Topcoat (Finish) 9.7. Chlorinated Rubber Paint for Topcoat (Finish) 9.8. Chlorinated Rubber Paint for Intermediate Coat 9.9. Chlorinated Rubber-Inhibitive Primer 9.10. Alkyd Paint (Aluminum) Leafing as Topcoat (Finish) 9.11. Alkyd Paint (Aluminum) Nonleafing as Intermediate 9.12. Alkyd Paint (High-Build Thixotropic Leafing Aluminum) as Topcoat (Finish) 9.13. Alkyd Paint (Black) as Intermediate and Topcoat (Finish) 9.14. Acrylic Silicon Finish Paint for Temperature Applications up to 200? 9.15. Vinyl Paint (Black) as Intermediate and Topcoat (Finish) 9.16. Silicone Alkyd Paint (White or Colored) as Topcoat (Finish) 9.17. Wash Primer (Basic Zinc Chromate-Vinyl Butyral) 9.18. Properties 9.19. Storage Life and Packaging 9.20. Vinyl Red Lead Primer 9.21. Material and Equipment Standard for Coal-Tar Epoxy Polyamide Paint as Primer, Intermediate, And Topcoat (Finish) Chapter 10: Technical Guidelines for Material Selection?art 2 Abstract 10.1. Vinyl Paint, (White or Colored) as Primer, Intermediate Coat, and Topcoat (Finish) 10.2. Two-Pack, Amine-Adduct, Cured Epoxy Paint as Primer, Intermediate, and Topcoat 10.3. Organic Zinc-Rich Epoxy Paint as Primer and Intermediate Coat 10.4. Zinc Silicate (Inorganic Zinc-Rich) Paint as Primer, Intermediate Coat, and Topcoat 10.5. Epoxy-Polyamide Primer 10.6. Epoxy Polyamide Paint as Intermediate Paint 10.7. Epoxy Polyamide Paint as Topcoat (Finish) 10.8. Coal-Tar Mastic Paint (Cold-Applied) 10.9. Two-Pack Aliphatic Polyurethane Paint as Topcoat (Finish) 10.10. Two-Pack Aliphatic Polyurethane Paint as Topcoat (Camouflage Colors) 10.11. Two-Pack Amine Cured Epoxy Resin Paint as Primer, Intermediate Coat, and Topcoat for Atmospheric Environments 10.12. Fast-Drying Synthetic Primer to be Used with Hot-Applied Coal-Tar or Bitumen (Asphalt) Enamel 10.13. Coal-Tar Primer (Cold-Applied) for Use with Hot-Applied Coal-Tar Enamel 10.14. Cold-Applied Bitumen Primer for Use with Hot-Applied Bitumen Enamel 10.15. Coal-Tar Enamel (Hot-Applied) 10.16. Bitumen Enamel (Hot-Applied) 10.17. Glass-Fiber Mat (Inner Wrap) 10.18. Coal-Tar-Impregnated Glass-Fiber Mat for Outer Wrap 10.19. Bitumen-Impregnated Glass-Fiber Mat for Outerwrap 10.20. Cold-Applied Laminated Plastic Tape as Inner-Layer Tape for Tape-Coating System of Buried Steel Pipes 10.21. Cold-Applied Laminated Plastic Tape as Outer-Layer Tape for Tape-Coating System of Buried Steel Pipes 10.22. Hand-Applied Laminated Tape Suitable for Cold-Applied Tape-Coating System 10.23. Hand-Applied Laminated Tape (Suitable for Hot-Applied Coating Systems) 10.24. Perforated Plastic Tape (as Rockshield) for Pipe Coating 10.25. Plastic Grid (as Rockshield) for Pipe Coating 10.26. Hand-Applied Petrolatum Tape and Primer 10.27. Heat-Shrinkable, Cross-Linked, Two-Layered Polyethylene Coating 10.28. Primers (Ditch and Yard) to be Used with Cold-Applied, Inner Layer Tape (Tape-Coating System of Buried Steel Pipe) 10.29. Primer to be Used with Hand-Applied, Laminated Tape Suitable for Cold-Applied Tape-Coating System 10.30. Primer to be Used with Hand-Applied, Laminated Tape Suitable for Hot-Applied Tape-Coating Systems Glossary of Terms References Index |

| Author | Alireza Bahadori |

| ISBN/ISSN | 9780128014073 |

| Binding | Paperback |

| Edition | 1 |

| Publisher | Elsevier |

You must be logged in to post a review.

Reviews

There are no reviews yet.